Barr Gaskets For Freezers & Coolers

The larger the number of people who require food, the bigger the refrigerator, commercial and industrial size should be, to keep up with the task. Another important aspect of the commercial refrigerator or industrial size is that it remains in good condition. This unit will face a daily workout that no homeowner would put any appliance through. These larger units will need routine and careful maintenance to stay in top shape.

The Condenser Coil

The daily grind for any part of the refrigerator, commercial or industrial in size, will take a toll on the condenser coil as well. The location of the condenser coils within larger or commercial refrigerator sized units will vary, but model specifics can generally be found online. Look at for the model number, and brand, when searching for this information. This part should be cleaned at least once a month to keep it free of kitchen debris, dirt, or dust build-up. Using a commercial condenser coil cleaner is recommended and these can usually be purchased anywhere kitchen equipment is found. The condenser fins should be brushed from top to bottom and never from side to side, and then the fins should be straightened.

Fan Blades and Motors for commercial refrigerator and Industrial Sizes

After the condenser is cleaned, the next phase should be the blades and motor. Here, too, there are typically some small pieces of debris and dust build up. Cleaning here is done with a soft cloth that is run over both the motor and the fan blades. When cleaning the blades on a commercial refrigerator or industrial size remember that when washing the blades, cover the motor with a dry cloth to keep any moisture from running down inside and causing damage. Washing is only truly necessary if there is caked-on grime; otherwise, a simple brushing with a damp rag can do the job.

Around the Refrigerator

Commercial units will be in a busy area, as the work of the kitchen flows around it. It’s a good idea to check around the unit for trouble spots that could be causing air flow problems, grease leaks or other issues to affect the use of the refrigerator. Commercial areas are generally busy and crowded, but some changes in this around the unit can make a big difference in the effective running of the refrigerator.

Inside the Refrigerator

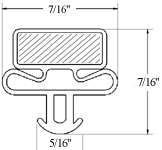

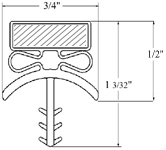

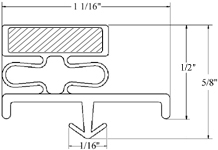

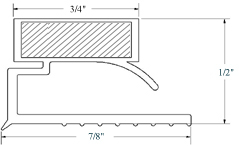

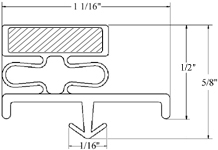

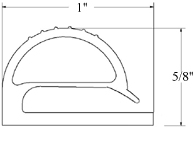

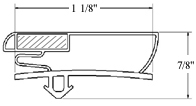

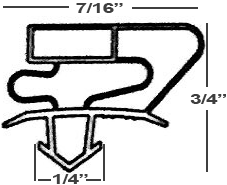

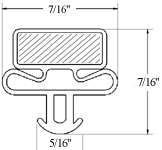

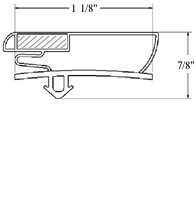

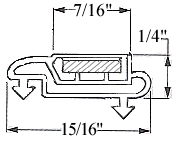

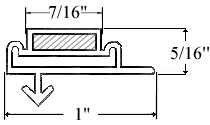

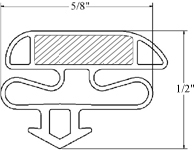

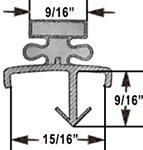

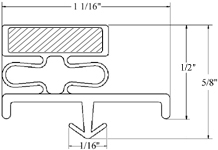

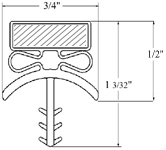

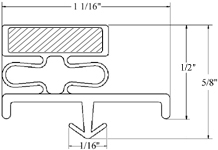

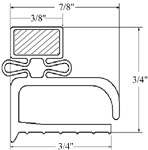

Commercial sized units should also be cleaned. Check the gasket first to see it there are rips, tears or pulls that will cause air to escape. Gaskets and gasket welders to make repairs can be found through Cooler Gaskets. A common mistake here that can be stopped by a qualified repair person is the practice of using too strong a detergent, bleach, or steel wool to clean the inside of the unit. Signs of this will be scratches or wear on the gasket and the insides of the unit. Solvents that involve only mild soap and warm water should be used. If the gasket is sticky, applications of warm water are often all that is needed, however, if this part is worn, it should be replaced. Commercial sized units are a challenge, but for those who are prepared, maintenance can be performed with ease.

The industrial size refrigerator needs specialized care, and this can often mean tougher equipment. Of extreme importance to most restaurants and food stores is keeping food safely cool while avoiding high-energy costs. The loss of cool air and the entrance of warm air also cause other parts of the unit to work harder, resulting in more costs and repair. Using welders can ensure from the start that the refrigerator is properly sealed, extending the life of both the seal and the unit. For those repairing or installing refrigerators, the proper use gasket welders can make all the difference, by protecting a customer from high energy and repair bills.

The Need for Gasket Welders

For a smaller refrigerator, re-sealing the door is a matter of locating the original screws and fixing the new gasket to the door, then tightening the screws. For the larger industrial door, this procedure is more involved, and can take longer without the use of gasket welders. With a gasket or thermo welder, along with the use of magnet cutters and gasket material, it is possible to make the correct size gasket for any job, making the gasket welder a necessary tool for either in-depth maintenance, or for the manufacture of gaskets.

Locating Gasket Welders

For the production of gaskets for the larger size or industrial model refrigerator gasket welders and other tools that can offer cooler running and energy saving units for customers when necessary, Cooler Gasket is one place to look for all materials necessary for these tasks, including the welders, gasket material, and magnet cutters. Rather than replacing a refrigerator, it is possible to place energy saving gaskets made of the correct material, and by doing so create a better situation for those needing this type of maintenance.

Gasket Welders and Enterprise

For those who need industrial or heavy refrigeration, the need for gasket welders who can change the effectiveness of their cooling units is becoming an industry. In the last few years, with energy costs at premium, businesses have started to look for new ways to save money, by using practical methods to save energy. It is possible to either buy new equipment that is designed to function on lower energy, or to replace parts that are not up to the challenge of efficiency. Here, those with the proper equipment and knowledge of gasket welders are much needed.

Tackling New Business Needs for Gasket Welders

Those who have larger than average refrigerators can find themselves paying heavily for energy use if this equipment is not properly maintained. Industrial size refrigerator units can be found in numerous places including schools, elder care facilities, government offices, grocery stores, and businesses with employee cafeterias, to name but a few. Each of these businesses or organizations represents a challenge for gasket welders, but also an opportunity. Few places are willing to replace equipment or to pay for wasted energy costs. The goal of most will be to find repair for gaskets that either leak, or have become damaged in some way. The use of gasket welders can help them avoid tougher business decisions.